If the size of the bag exceeds this range, we will consider customization.

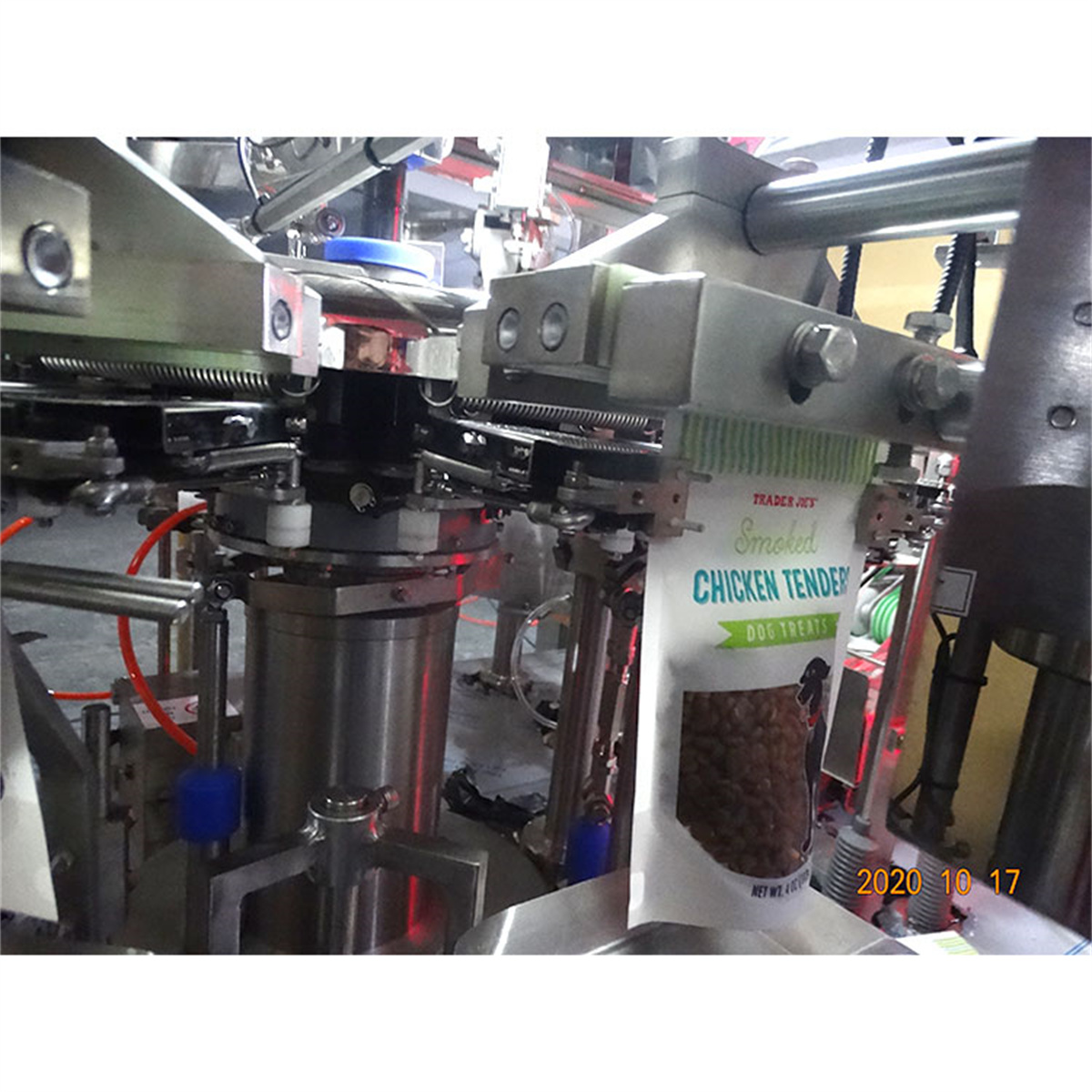

.jpg)

.jpg)

| Power supply | 380v 3phase 50Hz |

| Compressed air | about 5~8kgf/cm²,0.4m³/min |

| Drive method | Cam |

| Fill station | 2 |

| Sealing style | straight/net type |

| Workstation | 8/10 station |

| Bag Width | 80-270mm |

| Bag Length | 100-380mm |

| Pack compacity | 10g-3kg Up to 90 Pouches/Min |

| Various bag types | Stand up pouch, flat pouch, pe pouch, gusset pouch, zipper pouch, retort pouch, spout pouch |

| Noise from running machine | within 75db |

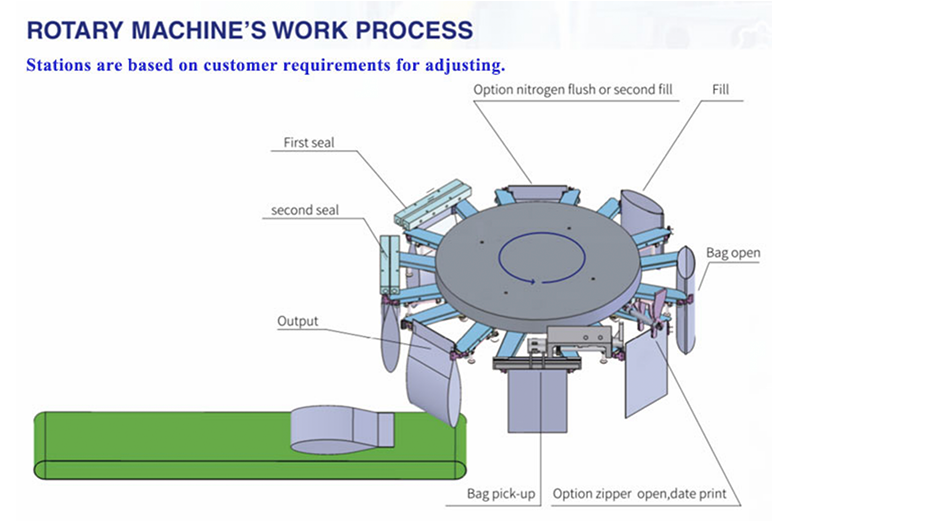

1.Bag pick-up

2.Optional Zipper open and Date print

3.Bag mouth and bottom open

4.Product fill

5.Option: Solid :Nitrogen charge,Powder: Bag mouth clean,Liquid:Secondary filling

6.First seal

7.Second seal

8.Output

Patented gripper system.

Patented gripper system.

Patented zipper open system.

Patented zipper open system.

Flexible and compatible with different volume devices and scales.

Flexible and compatible with different volume devices and scales.

Flexible pouch type: stand-up pouches with zipper, doypacks, flat pouch, corner spouts pouches, quad bottom pouches, gusset pouch and pouches with customers’ design, etc.

Flexible pouch type: stand-up pouches with zipper, doypacks, flat pouch, corner spouts pouches, quad bottom pouches, gusset pouch and pouches with customers’ design, etc.

Flexible capacity 15-90 pouches/min.

Flexible capacity 15-90 pouches/min.

Long work time and lifetime can work 24 hours a day, only one day off for maintenance per month.

Long work time and lifetime can work 24 hours a day, only one day off for maintenance per month.

Easy to operate and maintain, one person is enough, only a few spare parts need to change.

Easy to operate and maintain, one person is enough, only a few spare parts need to change.

It will take only about 15mins to change bag sizes by buttons on the touch screens.

It will take only about 15mins to change bag sizes by buttons on the touch screens.

A totally automatic packaging line, can replace at least 7 workers.

A totally automatic packaging line, can replace at least 7 workers.

Low energy costs.

Low energy costs.

Global after sales service, fast delivery of spare parts.

Global after sales service, fast delivery of spare parts.

All parts contacts products are 304 /316 food-grade stainless steel.

All parts contacts products are 304 /316 food-grade stainless steel.

Save pouches and products by sensors for fill and seal, if there is no pouch or pouch open error, there is no fill or seal.

Save pouches and products by sensors for fill and seal, if there is no pouch or pouch open error, there is no fill or seal.

We offer customized design layout according to different requirements.

We offer customized design layout according to different requirements.

Inquiry and consulting support, professional packing solution for free. We will be a consultant for clients about the technical problem before order, provide drawing specification, design customized project, analyze and solve technical problem.

Machine videos for your reference.

Sample packing testing support.

View our Factory.

Manules / Videos of machine installation, adjusting, setting, maintenance are available for you.

If any problems happend and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

Our engineers & technician are available send to your countries for services if you agree pay the expenditure.

Oversea service for our engineer is available. Clients need to afford the visa, tickets, accommodation, hotel and 120 USD per day.The problem components are free during the warranty time

Technical support

We will keep your machine's detailed file in the computer, such as the machine info, product info, your requirement and

suggestion, technician's advice and so on. And we will follow up and make feedback about the machines performance regularly. We guarantee that we will solve your problems as soon as possible.

Training

We can provide training service for you in machines' installation and commissioning. After all required production materials are ready in your factory, we will send technician to adjust the machine in good performance. As per the technician's instruction, the workers can learn how to connect power line, commissioning, machine working principles and the maintenance during operation and so on. So they will be more familiar with the operation of packing machine by training.

We will contact you with in 24 hours.